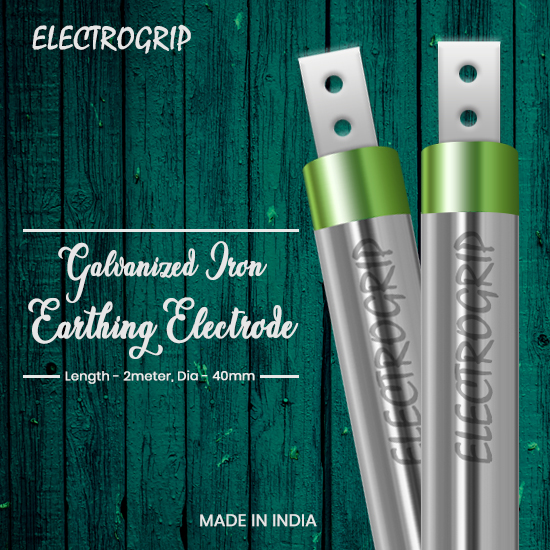

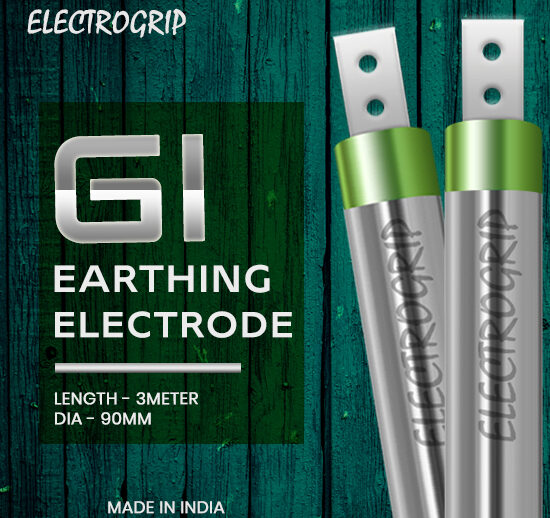

Electrogrip GI Earthing Electrode

GI earthing electrode is one of the electrical products of Electrogrip. The primary material that is used to manufacture this product is galvanized iron. The length of GI earthing electrode can be 2 meters or 3 meters and there are a lot of options for diameter of the electrode such as 40mm, 50mm 60mm, 80mm, 100mm and 110mm. As it is a galvanised iron rod there is a zinc coating of up to 100 microns as per your requirements and also the coating slows down the corrosion process and can work properly for around 6-7 years. The structure consists of two gi pipes and a plate and the gap is filled with a special kind of conductive chemical.

- Make an Enquiry

- Description

- Additional information

- Installation Guide

Quick Enquiry? Call us now

+916290918920

or send us an email

sales@elapp.in

Description

GI Earthing Electrode

GI earthing electrode is one of the electrical products of Electrogrip. The primary material that is used to manufacture this product is galvanized iron. The length of GI earthing electrode can be 2 meters or 3 meters and there are a lot of options for the diameter of the electrode such as 40mm, 50mm 60mm, 80mm, 100mm and 110mm. As it is a galvanised iron rod there is a zinc coating of up to 100 microns as per your requirements and also the coating slows down the corrosion process and can work properly for around 6-7 years. The structure consists of two gi pipes and a plate and the gap is filled with a special kind of conductive chemical.

Measurements with some gi earthing electrode specification:

| Length | Diameter | Coating | Material | Category |

| 2 meter | 40mm | Up to 100 micron | Galvanised Iron or GI | Chemical Earthing Product |

| 50mm | ||||

| 80mm | ||||

| 100mm | ||||

| 110mm | ||||

| 3 meter | 40mm | |||

| 50mm | ||||

| 60mm | ||||

| 80mm | ||||

| 100mm | ||||

| 110mm |

Material details:

This electrode is made of galvanised iron. As we all know being into the metal category, iron is considered as a conductive material. But due to its corrosive property, pure iron demands high maintenance when it is exposed to an open environment. So, in order to protect the iron from getting rust a coating of zinc is there and the galvanized iron is used here to make this electrode. It requires less maintenance and lasts longer than normal iron.

Working principle:

We have used the pipe in pipe technology here. A Galvanized iron pipe is installed here inside another galvanized iron pipe and the hollow space is filled with a special kind of chemical filling, which is called a crystalline conductive mixture. A small portion of the strip stays above the ground for connection purposes with two holes on it.

When a fault or short circuit occurs in the electrical line, the leakage current passes through the ground wire and it saves the electrical appliances and lives. It is one of the most important parts of electrical safety.

Advantages (gi earthing electrode specification):

There are several advantages of using a GI or Galvanised Earthing Electrode with great gi earthing electrode specification,

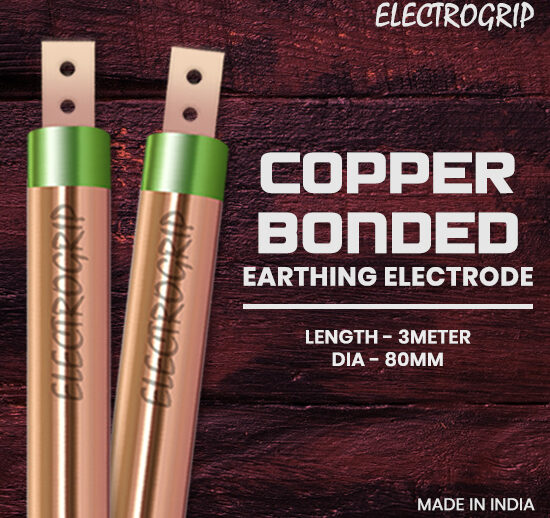

- The cost is less than the copper electrode.

- The corrosion process is comparatively slower than a normal iron rod.

- It lasts for more than 6-7 years.

Additional information

| Diameter of the Electrode | 40mm, 50mm, 60mm, 80mm, 90mm |

|---|---|

| Length of the Electrode | 2 Meter, 3 Meter |

| Electrode Terminal Size | 50mm x 6mm |

| Thickness of the Electrode Pipe | 1.6mm, 2mm |

| Standard Weight of 60mm x 3 Meter GI Electrode | 12 Kilograms |

| Standard Weight of 80mm x 3 Meter GI Electrode | 23 Kilograms |

| Galvanised Micron Coating | Up to 80 Microns |

The installation process of GI earthing electrodes is a hassle-free one. A hole needs to be dug in the ground. The width of the hole will be 8 to 10 inch and the depth will depend on the length of the earthing electrode. In case the GI earthing electrode is 2 meters long the depth of the hole will be approximately 1.8 meters and if it is 3 meters long the depth will be approximately 2.8 meters.

The GI earthing electrode is needed to be placed at the center are of the hole and the rest of the part of the hole has to be filler with an earthing chemical such as Electrogrip Back Fill Compound or Electrogrip Carbogem or Eletrotrogrip Conductive Gel in order to maintain the resistivity of the soil. The right process of filling is to mix the chemical compound with water then pour it into the hole. But if the water is poured after filling the chemical compound, it forms clots and the working efficiency gets hampered. That is why it is advised to mix the compound first with water and then fill it.